FAQ-Product

Frequently asked questions

Ball valves

Ball valves

Yes, some of our ball valve types are oil and grease free.

Differentiation:

"Oil- and grease-free dry" (e.B. dry compressed air, which must not contain grease)

"Oil and grease free for oxygen" (lubricants approved for oxygen are used)

Both come individually and vacuum-packed with marking

A general answer is not possible, as this depends on the medium, pressure, temperature, etc. As a rule, our ball valves are tested on about 500,000 switching cycles, there have already been successful tests with about 5,000,000 switching cycles.

Floating ball means that the ball does not have a fixed spindle - so on the one hand it can better compensate for movements of the ball due to high pressures and on the other hand it compensates for the acting forces of the lever and is therefore more durable and stable.

We strongly advise against such use. Ball valves are pure on/to valves and are not designed for control/dosing of media. For such an application, for example, a needle valve or a globe valve with regulating cone is recommended.

Yes, in the case of threaded ball valves this applies to our types GK06, in the case of flange ball valves these are the types FK01/02, as well as our series FK05. All types can also be equipped with a pneumatic single-acting, pneumatic double-acting or electric drive, stating the medium, operating pressure and temperature.

Unfortunately, we cannot offer our ball valves with Tri-Clamp connections, as we generally do not have a delivery option with clamp connections in the ball valve area.

An blow-out safe switching spindle prevents unplanned pushing out of the spindle due to overpressure in the line. This is due to the constructive design of the ball valves. During assembly, the spindle is inserted from the inside through the housing, then the ball is pushed into the housing and mounted in such a way that it cannot be pushed out of the housing. With conventional ball valves, the switching spindle is inserted into the housing from above/outside and can be pushed out or even shot out when overpressed.

A single-acting actuator has only one input for the compressed air. As long as the compressed air is applied, the valve is open (or closed in the case of NO valves). As soon as the compressed air is eliminated, the spring installed in the drive moves the valve back to the starting position. A 3/2-way Namur valve can be used for the electrical control of single-acting actuators.

Double-acting actuators have two inputs, so compressed air is required for each valve movement. The compressed air is only needed for the respective switching and does not have to be applied permanently. A 5/2-way Namur valve can be used for the electrical control of double-acting drives.

The basic individual components of the ball valves type GK12 consist of 1.4408. a. the individual components "thigh spring" and "guide nut" consist of stainless steel materials 1.4305 and 1.4310 respectively. These contain more residual ferrite and sulfur, which is why, as in this case, surface corrosion ("rust") occurs. This type of corrosion does not intervene in the material (deeper), but forms on the surface, which in turn represents a visual and not functional problem.

The switching time for pneumatic ball valves is about 1-2 seconds, depending on the drive size and control pressure.

With regard to absolute silicone-free and paint compatibility, we can not confirm.

The parts are silicone-free in production, but not individually packaged. This means that the parts can come into contact with silicones or the like at any time anywhere.

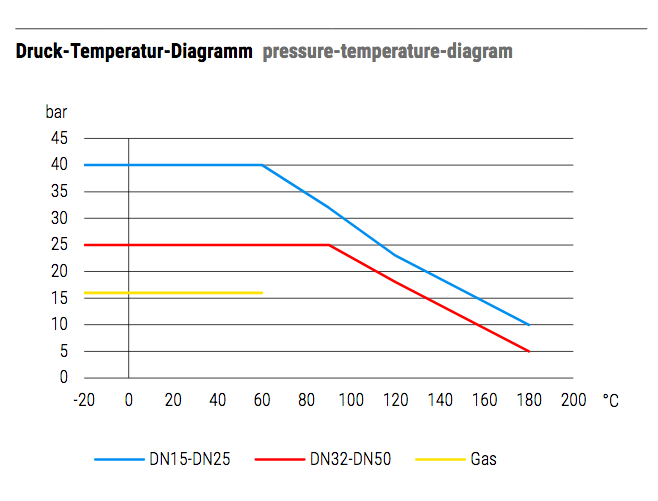

The ball valve is basically resistant to temperatures from -20°C to +180°C, depending on the operating pressure. However, DVGW gas approval is permissible from -20 to +60°C.

NieRuf offers the following certifications for its ball valves:

- DVGW Gas (certification for gas applications)

- DVGW Drinking water (certification for use in drinking water applications)

- Fire Safe

- TA Air

Certified ball valves can be displayed in the Ball valve category using the Certification filter.

Due to the three-part structure, these ball valves are particularly easy to maintain, as the middle part can be replaced very easily. The outer parts remain firmly connected to the pipeline and thus no additional welding or sealing work is necessary. The replacement of sealing rings and the housing seal are thus possible without great expenditure of time.

The lubricants/seals of our 3-way ball valves are not identical.

We only have compact ball valves with ISO Top, without the ISO structure we unfortunately have no delivery option.

Fire-Safe means that in the event of a possible melting of the seals, the ball settles in such a way that the medium cannot escape. As a rule, this is checked and confirmed by means of a Fire Safe certificate. Our series FK05 & FK12 have this test or approval. Our FK01 and FK02 series have the same design, but are not certified.

Yes, the hammer can also be ""switched"" via the overhang of the shaft.

This is usually done using a two-flat / 2-sided shaft BUT single-acting is spring-loaded to close or open, therefore very heavy. If compressed air is available, even a double-acting drive is difficult to switch by hand

A ball diverter valve is used in combination with safety valves. Two safety valves are attached to the end of the ball valve. The ball valve can be used to activate one of the two safety valves as desired, but not both of them. A ball diverter valve is used when the safety valves must be regularly maintained. This makes it possible to remove one of the safety valves and replace or maintain it without having to switch off the system completely.

We are here for you

Special requests, spare parts or a quick support? Our staff will answer your questions and concerns immediately.

Consultation

Mon. - Fri. from 08:30 - 17:00

Phone: +49 7143/9666-900

sales@nieruf.com

Brand promise

Committed

Commitment engenders trust. We stand by our word and are convinced that as a result not only our customers but also everyone we work with can rely on us.

Motivated

We always strive to find the best solution for our customers. It is our goal and incentive to have completely satisfied customers.

Competently

Technical and commercial expertise form the basis for developing qualified solutions tailored precisely to the needs of our customers.

Flexible

We do not adhere to rigid guidelines but instead focus on the individual wishes and needs of our customers. They are more important to us than internal company processes.

Contact

Contact  Resistance check

Resistance check  Frequently asked questions

Frequently asked questions  Configurator

Configurator