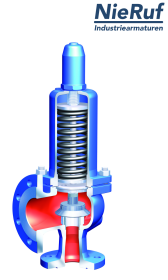

flange-safety valve DN20/DN20 SF0301, stainless steel metal, without lever

DN20 flange-safety valve gastight cap and closed bonnet for liquid and gaseous media made of stainless steel pressure 0,3 up to max. 40 bar

Technical features

- diameter DN20/DN20

- connection flange acc. to DIN EN 1092-1

- seal metal

- set pressure 0,3 up to max. 40 bar

- media liquid and gaseous media

-

Contact

Contact  Resistance check

Resistance check  Frequently asked questions

Frequently asked questions  Configurator

Configurator