Not just Clean, but Pure

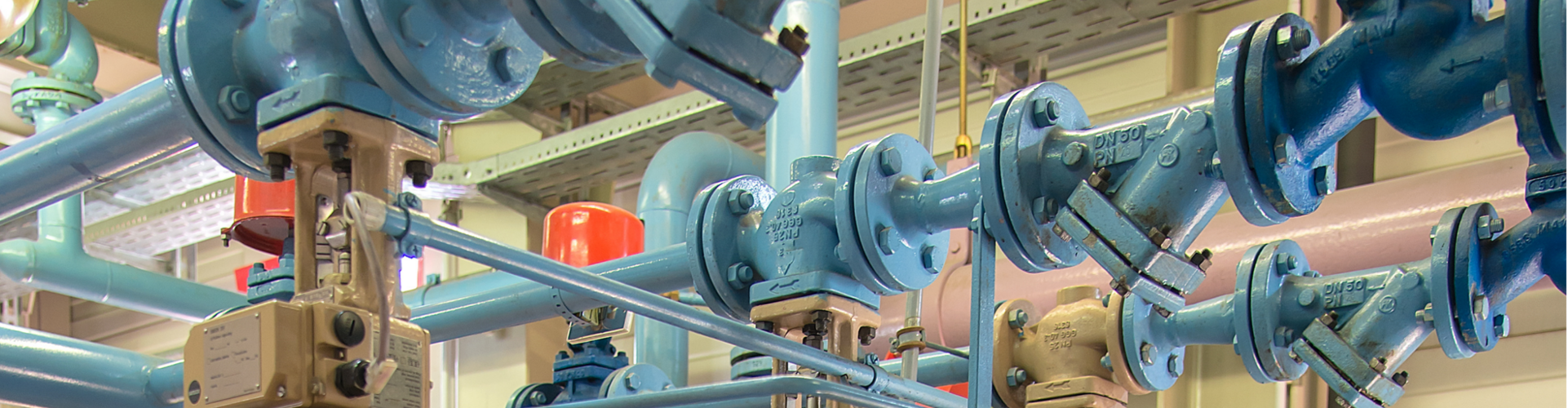

Unfortunately, many media often do not comply with the necessary level of purity for the corresponding production process. Therefore, an additional cleaning phase is essential. In gas and liquid pipe systems, strainers are used for this. These highly-effective “cleaners” filter even the smallest contamination from the media to be processed. The particles which have been filtered out are stored in the sieve basket intended for this.

Form the Name or Name the Form

With strainers we differentiate between different types – such as T-, pot-, clamp-, temporary- or Y-strainers. We purposefully specialise in the latter – Y-strainers. The name is derived from the shape of the housing, which resembles a Y. Like all cleaning fittings, Y-strainers also contain a fine sieve and a dirt-collecting sieve basket inside.

Easy Installation and Removal

In order to install or remove your Y-strainer as quickly and easily as possible, we recommend placing it in front of or behind ball valves. That simplifies the closing and opening of the pipelines. That is the basic requirement for removing, regularly cleaning and changing the strainer and sieve basket without leaking gas or liquid.

The Right Direction

You also have to make sure the direction is right when installing your Y-strainer, as it might otherwise not work properly or at all. The installation direction is depicted by an arrow on the fitting. In addition, flow and installation direction of your Y-strainer are explained extensively in the data sheet.

Y-Strainers for Everyone

We supply Y-strainers in many variants and for any possible application. Of course, with short delivery times and at good prices. Our product range includes Y-strainers made from stainless steel, brass and grey cast iron. With flange connection or thread connection. With the nominal sizes DN8 - DN300 or 1/4 – 12 inches. Caution: With aggressive media such as purified water, we recommend you exclusively use stainless steel strainers for longer durability.

Strainer Type SZ02 with thread in Y design cleans water and other liquid media. It is designed for pressures of up to 16 bar and for temperatures between -10°C and +120°C. The cap and housing are made from brass CW 617N according to DIN EN 12165. The O ring consists of EPDM. Furthermore, the equipment of the strainer type SZ02 with thread includes a BSP female thread with removable filter made from stainless steel 1.4301. The mesh size of the filter is 8.5/10° mm (850 µ). Please find more specifications in the data sheet on the article detail page.

The flange-strainer type SZ03 in Y design filters liquid and gaseous media. It is designed for pressures of up to 16 bar and has been optimised for temperatures between -20°C and +200°C. Housing, bonnet and cap are made from high-quality stainless steel 1.4408 – screws, washers and the filter are made from stainless steel 1.4301. The cap and housing seal are made from PTFE. Both – flange and strainer – are DIN-certified and fulfil DIN EN 1092-1 PN16 (flange) as well as DIN EN 12516-1 (strainer). The measurements of the flange-strainer type SZ03 correspond to EN 558, series 1. The fabric mesh can be chosen in 3 different measurement units: up to DN50 – 8/10° mm (800 µ), from DN65 to DN80 – 10/10° mm, from DN100 – 30/10° mm. Please find more specifications in the data sheet on the article detail page.

The flange-strainer type SZ04 in Y design is usually used in water supply and irrigation and cleans water as well as other liquid media. In terms of pressure, it is authorised for up to 16 bar and for temperatures between -10°C and +80 degrees Celsius. The housing is manufactured from GG25 grey cast iron and coated with Epoxy. The cap, screw connection and filter consist of stainless steel. The seal is made from high-quality EPDM. The flange connection fulfils DIN EN 1092-2 PN10/PN16 and withstands pressure tests according to EN 12266-1. Furthermore, the flange-strainer type SZ04 includes a draining cap, as well as a removable filter made from stainless steel 1.4301. Please find more specifications in the data sheet on the article detail page.

You Ask – We Answer

Should you have further questions about our cleaning fittings for gases and liquids, we are very happy to answer. Just call or send us an email.

Contact

Contact  Resistance check

Resistance check  Frequently asked questions

Frequently asked questions  Configurator

Configurator